Fruit jellies are among the most loved snack items for people of all ages. Known for its vibrant colors, fruity flavors, and delightful chewy texture, it has become a staple in many households. However, little is known about how these juicy delights come to the convenience store. Fruit jelly candy manufacturers use a specialized process that combines science, artistry, and creativity. In this article, JOJOSE FOODS the best fruit jelly manufacturer in China, reveals how fruit jellies are made by manufacturers, from the selection of ingredients to the final packaging of the finished candies.

- Ingredient selection and preparation

The first step in making fruit jelly candies is selecting high-quality ingredients. Manufacturers carefully choose fresh fruits or fruit juices to impart the desired flavor to the candies. Jellies are made from a variety of fruits, either from a single fruit or in combination with multiple fruits. The level of ripeness varies from one fruit to another. For instance, fruits like pears, peaches, apricots, strawberries, and raspberries gel best when lightly underripe. Whereas plums and cherries are best picked when they are just ripe, as the fruits are grown by the farmers, the quality manufacturer must develop a strong relationship with them in order to get the best quality fruits at the right time of the season.

Many fruit jelly manufacturers prefer their production plants near the fruit farms owing to the benefits of the time elapsed between harvest and preparation (only 12–14 hours).

Some of the most common fruits used in making fruit jellies are strawberry, orange, lemon, raspberry, and cherry, among others. Also at the selection stage, the choice for other crucial ingredients such as sugar, corn syrup, pectin, citric acid, and food coloring is carefully considered, keeping in mind the raw quality of such ingredients to add flavor, sweetness, and texture to the fruit jelly.

- Preparation

The next step is preparation. Fruits are prepared by being washed, peeled, and juiced to extract the desired natural flavor. Sugar and corn syrup are mixed to create a syrupy base, while pectin, a natural thickening agent derived from fruit peels, is added to help the candies set. Citric acid may also be included to balance the sweetness and add a tart flavor.

The most important thing to keep in mind during the preparation stage is that all the ingredients must be mixed in carefully measured amounts. Ideally, pectin should be 1%, sugar should be 65%, and acid concentration should be at pH 3.1. Factories ensure that the amount of pectin is in the appropriate quantity, as it can make the mixture too hard, or too much sugar can make the concentration too sticky.

Typically, there are three stages followed in the preparation stage:

- Inspection

When the fruit arrives at the manufacturing plant, it is thoroughly checked for quality factors such as its ripeness, color, and taste. Once it is approved in the inspection phase, it is then passed on to a funnel-shaped hopper that further carries the fruits into pipes for cleaning and crushing.

- Cleaning, crushing, and chopping

The second stage consists of the cleaning, cutting, and chopping phases. As the fruit undergoes a pipe, it is sprayed with gentle water that clears away any dirt or debris accumulated on the fruit. Depending on what is made out of fruits, such as jams or jellies, the fruit is then pushed by paddles through small holes to extract its juice and leave pulp and other things, such as stems, behind. Some fruits, such as citrus or apples, may be manually peeled, cored, sliced, and diced.

- Pasteurizing the fruit

Pasteurizing the fruits is the process of preserving them from spoilage. The fume is then passed to another pipe to cook vats. In cooking vats, the fruits are heated just below the boiling point (212°F [100°C]) and then immediately chilled to just below freezing (32°F [0°C]). This process is known as pasteurizing, which prevents it from spoiling.

When making jelly, the pulp is forced through another set of small openings to hold back the seeds and skin. The juice and fruit are transferred to large refrigerator tanks and then pumped to cooking kettles.

- Cooking the Jelly Mixture:

The prepared ingredients are then sent to be cooked in large stainless steel kettles or vats. The mixture is heated to a precise temperature, typically between 220°F and 240°F (104°C and 116°C), while being stirred continuously to prevent scorching and ensure uniform cooking. This cooking process activates the pectin and sugar, causing the mixture to thicken and develop the characteristics of a jelly-like consistency.

During the cooking process, the mixture is closely monitored to achieve the perfect consistency and fitness required to make a quality jelly. Some manufacturers may also add natural or artificial flavorings and colorings at this stage to enhance the taste and appearance of the fruit jellies.

- Pouring and moulding

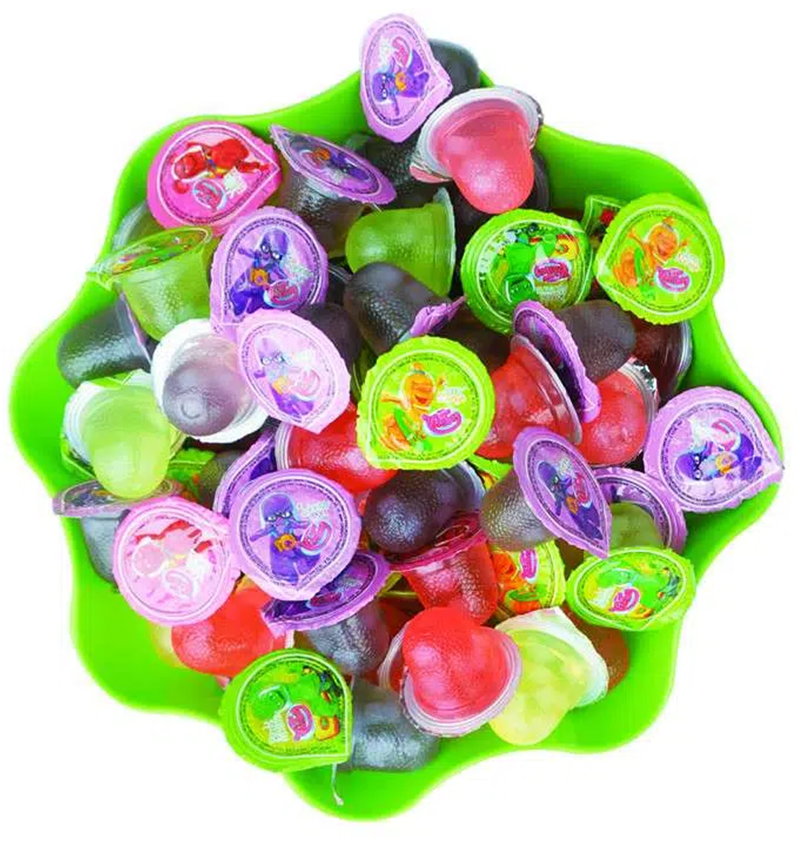

In this stage, the jelly is poured into the molds to bring the candies to a desired shape. These molds can vary in shape, size, and design to make jellies desirable and attractive to customers. After the molding process, the jellies are then transferred to a cooling chamber or conveyor belt to allow the candies to set and firm up. This cooling process may take several hours, during which the jellies solidify and develop their signature chewy texture.

- Demolding and coating:

Once the fruit jelly sets in the mold and gets its desired molded shape, fruit jelly candies are then removed from the molds; this process is known as molding. The candies are then inspected for quality and consistency to provide the best possible service to the customers.

Some manufacturers have different coating stations for fruit jellies to be coated for extra gloss, flavors, and textures to make jellies more appealing and attractive and make them look fresh.

- Packaging and Distribution:

The final step entails packaging the fruit jellies. Packaging has a strong impact on the sales of fruit jellies; hence, fruit jelly manufacturers pay extra attention to the packaging factor. Packaging may include labeling with product information, ingredient lists, nutritional facts, and branding elements such as logos and artwork. According to the packaging law, packaging must be truthful and honest.

Conclusion

In conclusion, the process of making fruit jelly candies by manufacturers involves the meticulous selection of high-quality ingredients, precise preparation techniques, cooking, molding, coating, and packaging. Through a combination of science, artistry, and innovation, manufacturers create delicious and visually appealing candies that delight consumers worldwide.